When the carbon content increases its strength increased but ductility decreases. Medium-carbon steel has approximately 0306.

Carbon silicon manganese sulfur and phosphorus are the main impurity elements in pig iron and carbon steel.

What is the composition of carbon steel. Iii Mild steel containing 020 to 030 carbon has a tensile strength of 555 MPa and hardness of 140 BHN. It is used for making gears valves connecting rods crankshafts railway axles fish plates small forgings etc. Medium carbon steel contains carbon from 03 to 060.

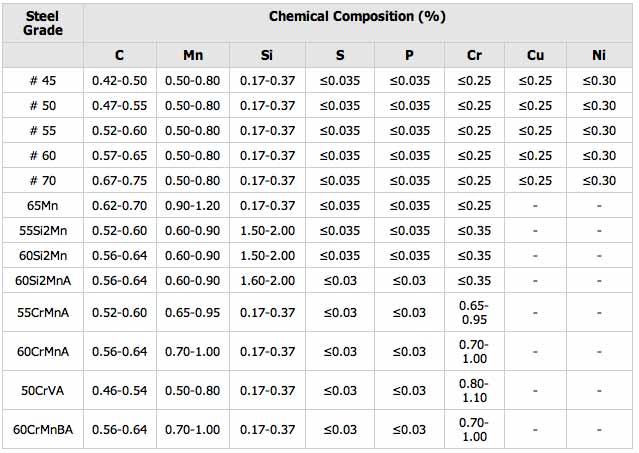

Steel containing 03-045 carbon has tensile strength of 750 Nmm 2. Chemical Composition Of Carbon Steel Pipes 1. Carbon silicon manganese sulfur and phosphorus are the main impurity elements in pig iron and carbon steel.

In structural steels and chromium chromium can significantly improve strength hardness and wear. Carbon steel is steel with carbon content up to 21 by weight. The definition of carbon steel from the American Iron and Steel Institute AISI states.

Steel is considered to be carbon steel when. No minimum content is specified or required for chromium cobalt molybdenum nickel niobium titanium tungsten vanadium or zirconium or any other element to be added to obtain a desired. Medium-carbon steel has approximately 0306 carbon content.

For example a 1040 steel is a plain carbon steel containing 040 wt C. Composition of Medium-carbon Steel Medium-carbon steel is mostly used in the production of machine components. Medium-carbon steel has approximately 0306.

Composition of High-carbon Steel. High-carbon steel has approximately 060 to 100 carbon content. The four major alloying elements that form carbides in tool and die steel are.

Tungsten chromium vanadium and molybdenum. Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools. Steel alloy of iron and carbon in which the carbon content ranges up to 2 percent with a higher carbon content the material is defined as cast iron.

Mild steel - 005-025 carbon and up to 04 manganese and rest is Iron. Medium Carbon Steel- 029-054 carbon with 060-165 manganese. High Carbon Steel-055-095 carbon with 030-090 manganese very high Carbon steel- 096-21 carbon it is brittle steel.

I can answer only first question according to the answering guidelines. Steel consists mainly of iron and carbon at almost 98 and 1 and very littl view the full answer Previous question Next question. Steel - iron enriched with carbon in the smelting process.

Carbon smelting is characterized by the presence of carbon which determines the basic properties of the metal and impurities. Phosphorus up to 007 silicon up to 035 sulfur up to 006 manganese up to 08. So low carbon steel contains not more than 025 carbon.

As for other additives manganese and. Material S235J0 propertiesOur hot rolled mild steel sheets offer excellent corrosion resistance property in the servers environments The mild steel sheets provide high resistance to nitric and chloride corrosion in sulfide solutions These SA283 GrC carbon stel plates offer high strength tensile yield mechanical strength ductility hardness toughness etc Mild steel sheet is worked. Carbon is the most important chemical element in the steel.

When the carbon content increases its strength increased but ductility decreases. The carbon content in the steel is normally in the range of 020 to 030. The peak value of carbon content is.

SAE AISI 1018 steel is one of the commonly used low carbon steels. It is usually used as carburized steel. Since most of the 1018 carbon steel is produced by cold drawing this cold rolled steel is called C1018 1018 cold rolled steel.

AISI C1018 steel 1018 CRS has good weldability surface hardening quality higher mechanical properties and better machinability. Cold drawing increases. Carbon steel composed simply of iron and carbon accounts for 90 of steel production.

Low alloy steel is alloyed with other elements usually molybdenum manganese chromium or nickel in amounts of up to 10 by weight to improve the hardenability of thick sections. Carbon is the principal hardening element in steel. Hardness and strength increase proportionally as Carbon content is increased up to about 085.

Carbon has a negative effect on ductility weldability and toughness. Carbon range in ULC Steel is usually 0002 0007. The minimum level of Carbon in Plain Carbon Steel and HSLA is 002.

Plain Carbon Steel grades go up to 095. Though they have the same basic composition of iron and carbon steel types tend to have a variety of alloying elements. Carbon steel tends to have under 105 chromium content but steel must be at least 105 chromium to be considered stainless.

Carbon steel refers to an iron-carbon alloy with a carbon content of less than 2 and containing a small amount of impurity elements such as silicon phosphorus sulfur and oxygen. According to its carbon content these types of steel can be divided into. Low carbon steel also known as iron or mild steel has a carbon content of 004-025 or 030.