Reducing the time cost and environmental footprint of manufacturing processes continues to be a major driver of technology development. PI is directed toward.

Lead to plant footprint reduction by 10 to.

Process intensification in chemical industry. Process Intensification methodologies have been extensively applied to improve the performance of several chemical processes. This chapter aims to give a description of some process units designed on the basis of Process Intensification concepts pointing out on their major features on the advantages determined by their exploitation in the chemical industry and on the existing barriers. This chapter aims to give a description of some process units designed on the basis of Process Intensification concepts pointing out on their major features on the advantages determined by their exploitation in the chemical industry and on the existing barriers that in some cases are currently limiting their spread on an industrial scale.

Process intensification is considered to be one of the most promising progress paths for development of more sustainable chemical processes Van Gerven and Stankiewicz 2009. There are different definitions of process intensification PI in the literature one this author favours is Any chemical engineering development that leads to a substantially smaller cleaner safer and more. Conference on Process Intensification in the Chemical Industry Ramshaw one of the pio-neers in the field defined process intensifica-tion as a strategy for making dramatic reduc-tions in the size of a chemical plant so as to reach a given production objective 2.

These reductions can come from shrinking the size of. Process Intensification In Chemical Engineering Engineering Essay Overall kinetics bla. In considering thermodynamics heat transfer within or across the boundaries of.

PI Area of Concern in Reaction Engineering Applications. Heat exchange in reaction engineering. Introduction 16 17 Process Intensification PI targets dramatic improvements in manufacturing and processing by 18 rethinking existing operation schemes into ones that are both more precise and efficient than 19 existing operations.

Process intensification PI is a rapidly growing field of research and industrial development that has already created many innovations in chemical process industry. PI is directed toward. Endorsed by the Working Party on Process Intensification of the European Federation of Chemical Engineering EFCE Chemical Engineering and Processing.

Process Intensification aims to be the premier publication for research contributions on process intensification concerning the chemical process industry. It will provide a basic knowledge of chemical engineering principles and process intensification for chemists and engineers who may be unfamiliar with these concepts. It will be a valuable tool for chemical engineers who wish to fully apply their background in reaction and separation engineering to the design and implementation of green processing technologies based on process intensification principles.

Process intensification could help to enable these new technologies. Two fundamental tenets have driven chemical engineering over the last century. The first is economy of scale which reasons that constructing larger chemical plants improves capital efficiency and resource utilization thereby reducing operating costs and product price as well as increasing profit.

Process intensification tools such as the capillary reactor offer several benefits to the chemical process industries due to the well-defined high specific interfacial area available for heat and mass transfer which increases the transfer rates and due to low inventories they also enhance the safety of the process. Chemical Process Intensification Promoting a safe efficient and clean chemical industry by developing advanced intensified reactor concepts through state-of-the-art fundamental knowledge obtained by advanced reactor modelling and novel experimental techniques. From numerical models to experimental proof-of-concept.

The design of intensified reactors and equipment is a chemical engineering challenge requiring new fabrication techniques and a thorough understanding of fluid mechanics. Design is aided by simulation tools which can be used to better understand the interaction of the key processes of mass and heat transfer and reaction. Process intensification PI is a chemical and process design approach that leads to substantially smaller cleaner safer and more energy-efficient process technology.

A hot topic across the chemical and process industries this is the first book to provide a practical working guide to understanding and developing successful PI solutions that deliver savings and efficiencies. Process intensification PI is a chemical and process design approach that leads to substantially smaller cleaner safer and more energy efficient process technology. A hot topic across the chemical and process industries this is the first book to provide a practical working guide to understanding.

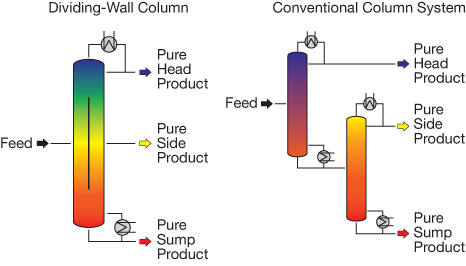

Reducing the time cost and environmental footprint of manufacturing processes continues to be a major driver of technology development. Process intensification for small molecule API production using flow chemistry technologies gives our clients greater opportunities to implement optimum process solutions on the commercial scale. A Paradigm Shift in Chemical Process Design Intensification of transfer and reaction rates lead to process equipment size reduction Integration of process steps another rather more important but less spoken face of PI ie.

Combining several process steps into one. Lead to plant footprint reduction by 10 to. Because of the electrolyte mixture we choose ELECNRTL method to get accurate parameters.

Process Intensification has gained a momentum as a revolutionary approach to chemical process in around last two decades. PI has been described as the key to survival of the fittest in international competition.