Manipueira wastewater of cassava Manihot esculenta processing can be treated by anaerobic biodigestion. In conventional ASP the flow model in aeration tank is plug flow type.

Lucia Brisbane Queensland 4072 Australia.

Plug flow wastewater treatment. Wastewater treatments systems are usually thought of as a plug flow complete mix or some hybrid type reactor. While most people know the definition of the reactors they do not know when one is preferred over another. 58 Upward plug flow of water and flowing bubbles with corresponding diameters.

This steady-state experiment can be carried out. With clean water and Na2SO3 resulting in an oxygen-free liquid system with real wastewater with or without activated sludge. Let us discuss the first case.

For the steady-state oxygen gas balance we write. Plug flow A type of flow that occurs in tanks basins or reactors when a slug of water or wastewater moves through a tank without dispersing or mixing with the. Plug Flow involves relatively long and narrow aeration basins so that concentration of soluble substances and colloidal and suspended solids Types of Activated Sludge Process Plug Flow Complete Mix SBR.

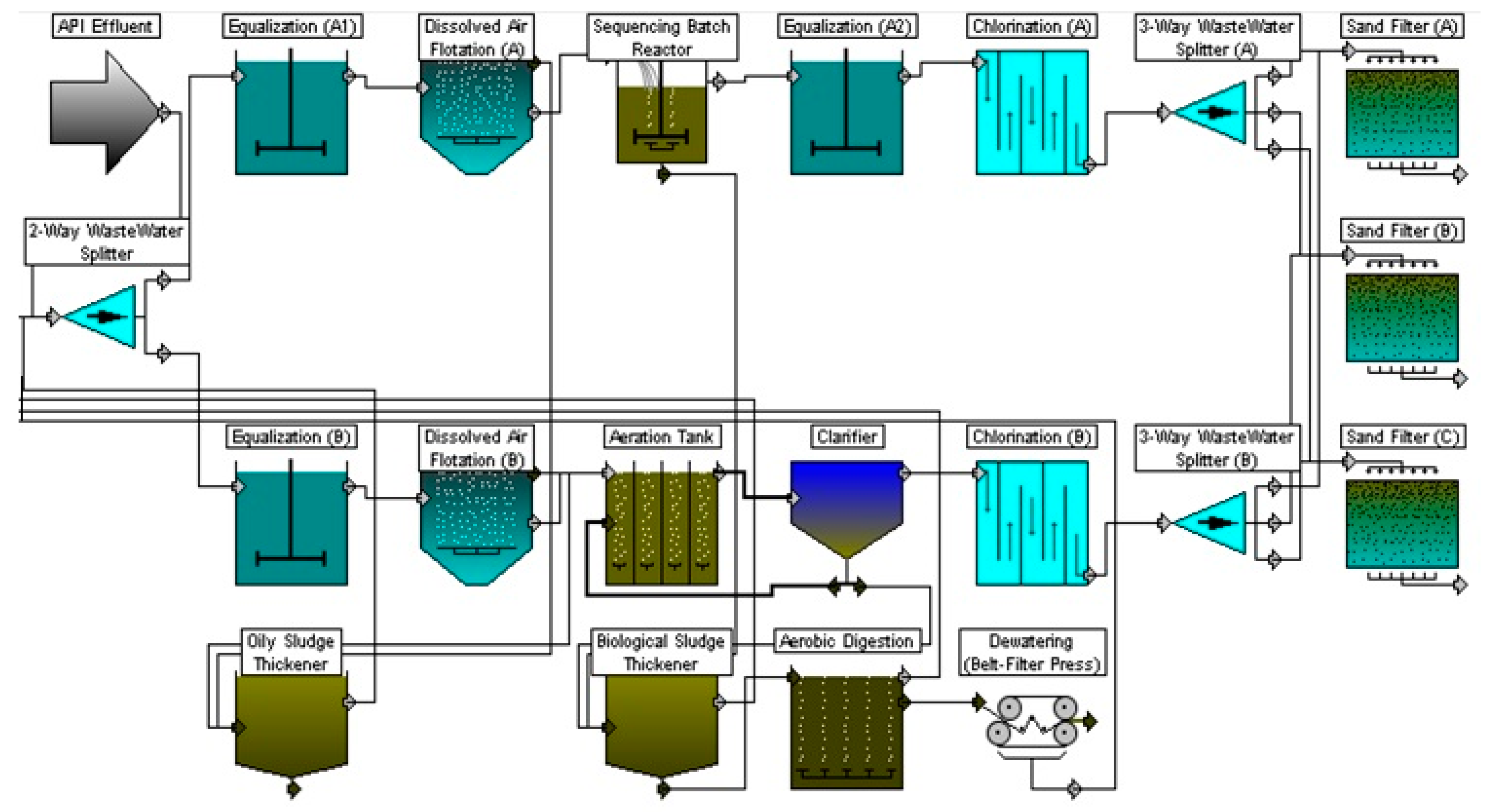

Conventional plug-flow activated sludge process. Conventional plug-flow schematic diagram is as shown above. Basically raw wastewater will first enter a primary clarifier whereby a certain percentage of sludge is left to settle before the wastewater is fed to the aeration tank.

Plug flow reactors Tubular Flow Reactors is a type of continuous flow reactor. Has been given to the study of the performance of treatment facilities because of its importance in the conventional treatment of wastewater. Hence the literature review related to the evaluation of the entire treatment.

In conventional ASP the flow model in aeration tank is plug flow type. Boththe influent wastewater and recycled sludge enter at the head of the tank and are aerated for about 5 to 6 hours for sewage treatment Figure 194. The influent and recycled sludge are mixed by the action of the diffusers or mechanical aerators.

Units are the vessels or basin that holds wastewater for the treatment by chemical or biological processes. They can be of any shape. Depending upon the flow and operating conditions and the methods of mixing of the wastewater therein the reactors have the following main types.

Continuous-Flow Stirred Tank Reactor CFSTR or Completely-Mix Reactor. Affiliations 1 National Engineering Laboratory for Advanced Municipal Wastewater Treatment and Reuse Technology Engineering Research Center of Beijing Beijing University of Technology Beijing 100124 PR China. 2 National Engineering Laboratory for Advanced Municipal Wastewater Treatment and Reuse Technology Engineering Research Center of Beijing Beijing University of Technology Beijing.

Full-Scale Modeling Explaining Large Spatial Variations of Nitrous Oxide Fluxes in a Step-Feed Plug-Flow Wastewater Treatment Reactor. Ni BJ1 Pan Y1 van den Akker B2 Ye L13 Yuan Z1. 1Advanced Wastewater Management Centre The University of Queensland St.

Lucia Brisbane Queensland 4072 Australia. Plug Flow Digesters Peter Wright Manure Treatment Specialist Department of Biological and Environmental Engineering Cornell University Scott Inglis Research Associate. Anaerobic Digestion Systems Biological Manure and Effluent Handling Separation Gas Collection.

Manipueira wastewater of cassava Manihot esculenta processing can be treated by anaerobic biodigestion. To study the start-up process of a plug-flow digester for manipueira treatment this work consisted of two stages. Gradual decrease of the hydraulic retention time HRT to the preset time of 4 days.

A horizontal plug flow and stackable pilot microbial fuel cell for municipal wastewater treatment. In this paper aiming at large scale MFC reactor for wastewater treatment we designed and operated a stackable horizontal plug-flow microbial fuel cell SHMFC. Real sewage was used as substrate without adding any additional nutrition or salts.

In wastewater treatment the activated sludge process is the most common applied method for biological nutrient removal BNR. This process includes aerobic oxidation of ammonia to nitritenitrate nitrification - followed by anoxic conversion of nitratenitrite to free nitrogen denitrifikation with N 2 O as an intermediate. Often an anaerobic step neither oxygen nor nitrate will be included as well to.