A laboratory test procedure for determining the wear of materials during sliding using a pin- on-disk apparatus. 2021 Google LLC.

Pin and Vee Block Tester.

Pin on disk wear test. Pin-on-Disk Wear Test Pin-on-Disk Wear Testing of Biomaterials Used for Total Joint Replacements. Figure 2 shows a schematic of the pin-on-disc wear test rig with the. Wear prediction in dental composites.

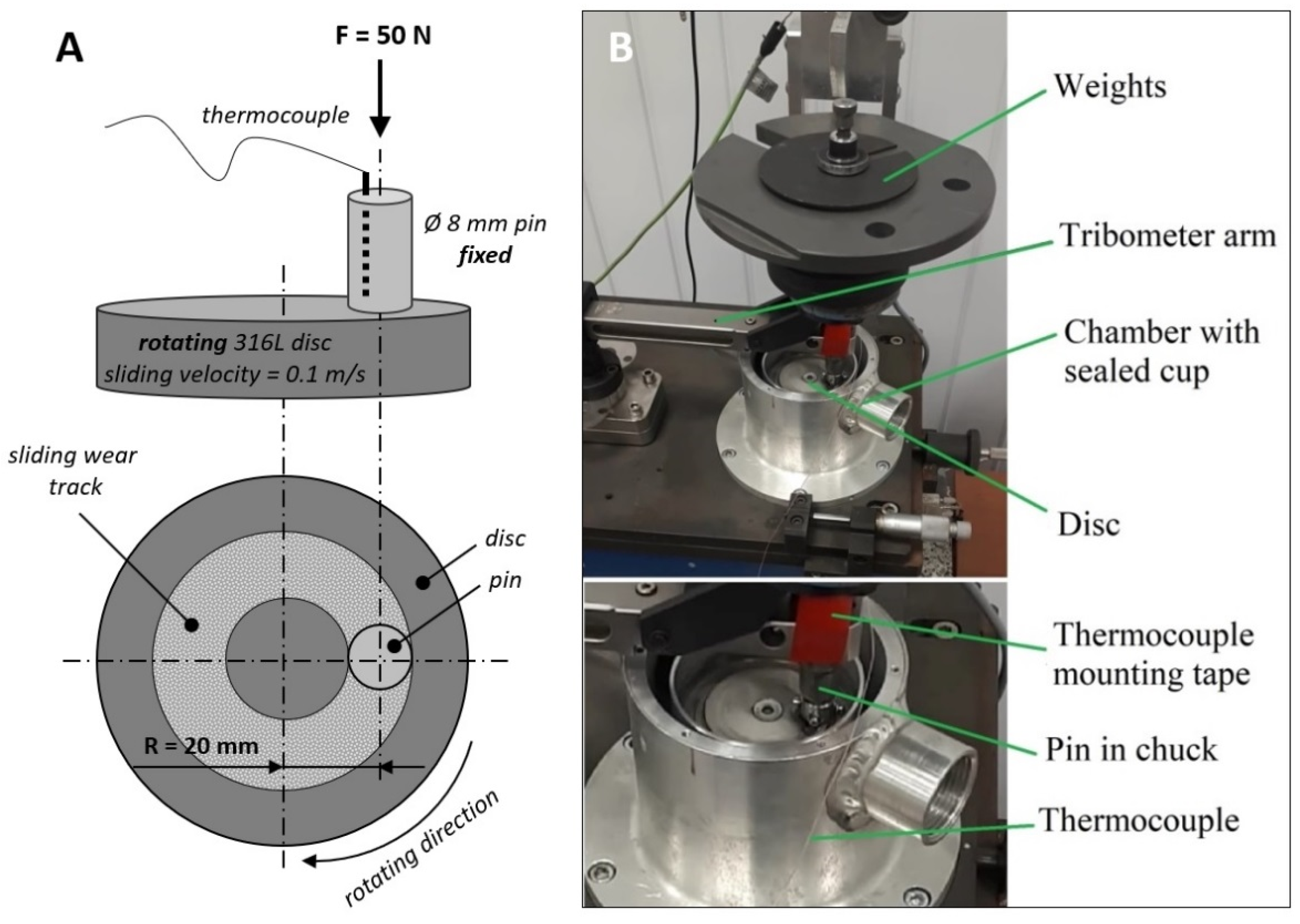

Summary of Test Method 31 For the pin-on-disk wear test two specimens are re-quired. One a pin with a radiused tip is positioned perpen-dicular to the other usually a flat circular disk. A ball rigidly held is often used as the pin specimen.

The test machine causes either the disk specimen or the pin specimen to revolve about the disk center. Since the pin-on-disk test method does not attempt to duplicate all the conditions that may be experienced in service for example. Lubrication load pressure contact geometry removal of wear debris and presence of corrosive environment there is no insurance that the test will predict the wear rate of a given material under conditions differing from those in the test.

Summary of Test Method31 For the pin-on-disk wear test two specimens are required. One a pin with a radiused tip is positioned perpendicular to the other usually a flat circular disk. A ball rigidly held is often used as the pin specimen.

The test machine causes either the disk specimen or the pin specimen to revolve about the disk center. G 99 - Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus Scope. A laboratory test procedure for determining the wear of materials during sliding using a pin- on-disk apparatus.

Materials are tested in pairs under nominally non-abrasive conditions. What is Pin on Disk Tribometer. The ball or pin on disk wear testing machine presses stationary pin or ball against the rotating disk.

Measure coefficient of friction COF friction force wear rate wear volume temperature and several other tribology parameters. Cost and efficient wear tester pin on disc used in the metallurgy research field. The purpose o f this pro ject is to study t he applicat ion of the pr inciple o f friction o n a pin into the c.

The pin-on-disk tester is one of the most recognizable and frequently-used tribotesters. It consists of a stationary pin which under the influence of dead weight rests on a rotating disk. Furthermore this type of tester can be put in a climate chamber to provide a controlled environment which is especially important when testing friction and wear of some plastics and ceramic materials.

The pin can have. Pin on Disk Test. Oil Viscosity Index and Viscosity Temperature Relation.

Power Spectral Density of Rough Surfaces. Coefficients of Kinetic and Static Friction. Pin on disk test.

Pin and Vee Block Tester. ASTM D2266 DIN 513505 IP 239. Four ball wear tests.

ASTM D2266 D3702 D4172. Pin on drum wear tester. Block On Ring Test.

Galling resistance test of materials. Reciprocating Ball-on-Flat Sliding Wear. Pin on Disc Wear Test Rig is designed to study friction and wear characteristics in sliding contacts.

Sliding occurs between a stationary pin and a rotating disc. Normal load and wear track diameter can be varied. Tangential frictional force and wear are monitored with.

To assess this hypothesis a new pin-on-disk tester was developed capable of unidirectional and bidirectional motion. Unidirectional motion produced no detectable wear. The rectangular motion produced wear rates surface morphologies and wear particles consistent with human acetabular specimens.

The results for 1 Hz and 2 Hz were similar. Pin-on-Disc Pin-on-Disk Wear Testing of Biomaterials Used for Total Joint Replacements. POD wear testing is.

Application of Carbon Based Nano-Materials to Aeronautics and Space Lubrication. Wear of internally lubricated polymers. In a pin-on-disc wear tester a pin is loaded against a flat rotating disc specimen such that a circular wear path is described by the machine.

The machine can be used to evaluate wear and friction properties of materials under pure sliding conditions. Either disc or pin can serve as specimen while the other as counterface. Pin on disc abrasive wear test - YouTube.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features. 2021 Google LLC. Wear tests pin -on disktype 2 Introducing test equipment MT The control of the friction and wear in movable pieces of machines is a critical element to face in the industry.

It is important to have comparable data of analyses obtained during years with variable humidity and temperature andor in the presence of. The Pin on Disc Friction Wear Test Rig is primarily intended for determining the tribological characteristics of wide range of materials under various conditions of normal loads temperatures under dry lubricated conditions with different environmental conditions.