Finished battery designs may use a plastic insulating wrapper shrunk over the case to provide. Batteries based on nickel-metal hydride NiMH with an aqueous electrolyte are both eco-friendly and safe.

Section VI Accidental Release Measures Personal Precautions Forbid unauthorized person to enter.

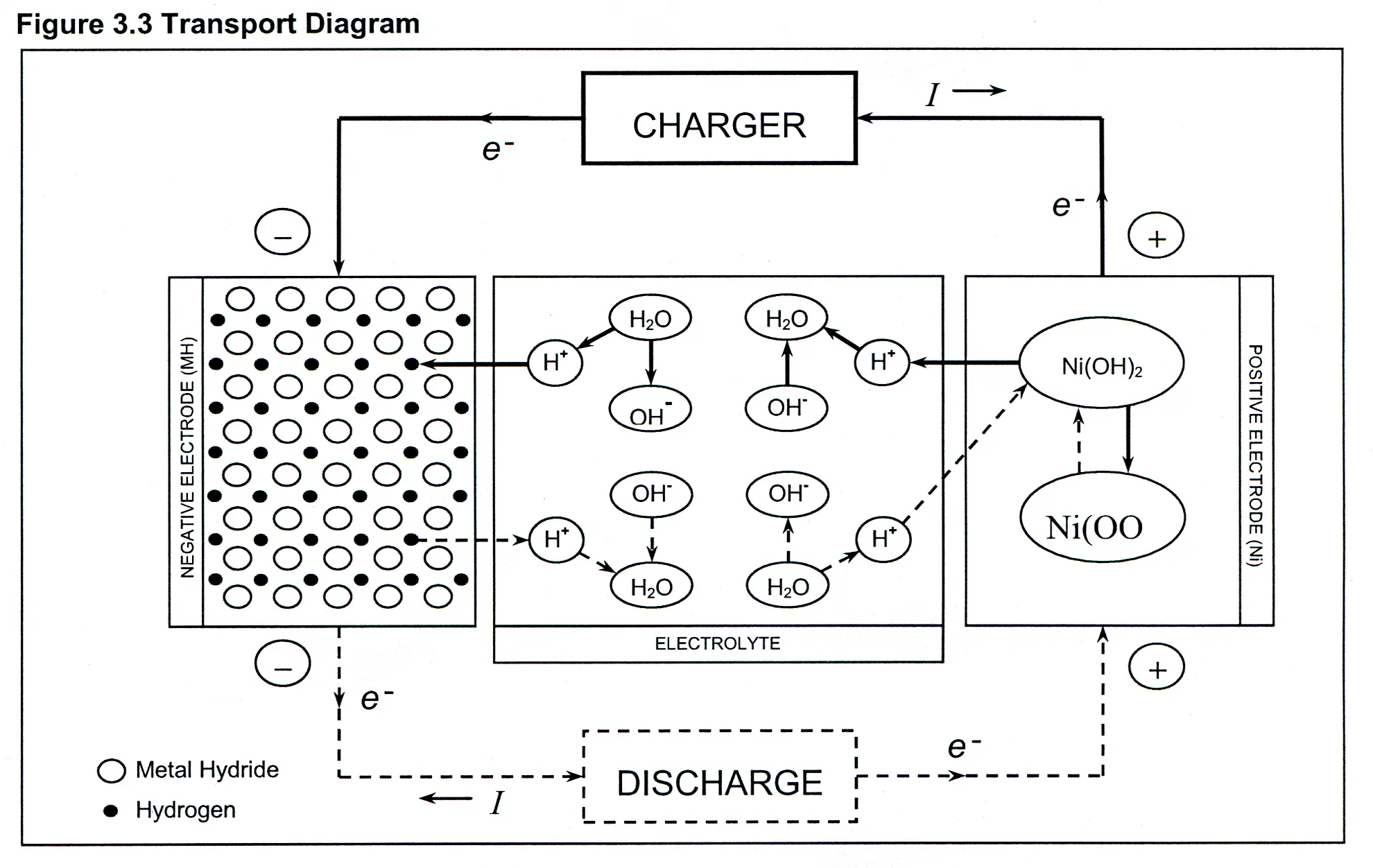

Nickel metal hydride battery construction and working. Construction Working of Nickel Metal Hydride battery lecture with explanation of all the reactions occurring at the anode cathode. Nickel Metal Hydride NiMH Battery. The principles in which NiMH cells operate are based on their ability to absorb release and transport move hydrogen between the electrodes within the cell.

Metal Hydride such as AB2 Atitanium andor Vanadium B Zirconium or Nickel modified with chromium Cobalt iron andor manganese. Nickel-metal hydride batteries are typically sealed designs with metallic cases and tops that are electrically insulated from each other. The case serves as the negative terminal for the battery while the top is the positive terminal.

Finished battery designs may use a plastic insulating wrapper shrunk over the case to provide. The nickel-metal hydride couple lends itself to the wound construction which is similar to that used by cylindrical nickel-cadmium battery. Nickel-metal hydride batteries contain a resealable safety vent built into the top.

The nickel-metal hydride battery is designed so the oxygen recombination cycle described earlier is capable of recombining gases formed during overcharge under normal operating conditions. The basis of regulating the nickel-metal-hydride battery is state-of-charge of BES system and voltage generated by the hybrid sources consist of photovoltaic and wind energy systems. Nickelmetal hydride and nickelcadmium batteries are often collected together and they can be handled in the same recycling plant.

Recovered cadmium is upgraded to high-purity metal and is used in new batteries and other applications such as pigments or coatings. Nickel and iron from NiMH and NiCd batteries are used in the steel industry. Recovery of nickel from batteries is profitable which.

The working of the nickel-cadmium battery is based on the chemical reaction taking place between the layers. The battery which is a source of DC voltage consists of two ports ie. While making the battery first the cadmium layer is kept on the redox.

The cadmium layer acts as the cathode terminal. Cadmium is one of the heavy material and has good conducting properties. Above the cadmium layer.

We produce all kinds of solar batteries power banks electric car batteries Batteriesvip Nickel metal hydride battery _The most comprehensive battery customization platform The store will not work correctly in the case when cookies are disabled. Ovshinsky invented and patented the NiMH battery and founded Ovonic Battery Company in 1982. NiMH works on the principle based on the absorption release and transport of Hydrogen within the two electrode.

Nickel metal hydride battery is much more environmentally friendly as it doesnt contain toxic materials like cadmium. Operating temperature and working conditions. Another plus on the side of the nickel metal cadmium battery is its endurance in rough working conditions.

It can handle high and low temperatures and vibration very well thus they also offer better resistance to impact. The first flexible solid-state nickelmetal hydride NiMH battery is developed by using a novel free-standing porous nickel matrix with tunable pore structu. Batteries based on nickel-metal hydride NiMH with an aqueous electrolyte are both eco-friendly and safe.

The NiMH battery is developed from the nickel-hydrogen battery NiH 2. Nickel metal hydride batteries can produce toxic fumes including oxides of nickel cobalt aluminum manganese lanthanum cerium neodymium and praseodymium. Protective equipment written in Section VIII.

Section VI Accidental Release Measures Personal Precautions Forbid unauthorized person to enter. Remove leaked materials with. Direct recycling is the removal of the cathode or anode from the electrode reconditioned and then reused in a new battery.

Mixed metal-oxides can be added to the new electrode with very little change to the crystal morphology. The process generally involves the addition of new lithium to replenish the loss of lithium in the cathode due to degradation from cycling. Cathode strips are obtained from the dismantled batteries.

The Nickel Metal Hydride NiMH battery has become pervasive in todays technology climate powering everything from cellular phones to hybrid electric vehicles. The NiMH battery started its life as an evolution from the nickel hydrogen battery used in aerospace applications. As a point of interest the metal hydrides used in NiMH cells can normally hold between 1 and 2 hydrogen by weight.

NiMH Nickel Metal Hydride battery technology has taken over from NiCds. Although they were originally envisaged as an interim solution they have found their niche in being used for the replaceable batteries like the standard AAA AA C and D size cells. Batteries for use in.