Rather than using liquid metal as the feed material SSM casting uses a higher viscosity feed material that is partially solid and partially liquid. The accreditation was issued in December 2016 by the South African Bureau of Standards SABS.

As a means to add value to the casting industry in South Africa the Metal Casting Technology Station MCTS located at the University of Johannesburg UJ.

Metal casting technology station. The University of Johannesburgs Metal Casting Technology Station MCTS is an initiative of the then LN1 Department of Science and Technology now Department of Science and Innovation - DSI under the Technology Innovation Agency TIA. The MCTS operates under the Faculty of Engineering and the Built Environment in partnership with the Department of Metallurgy. The University of Johannesburgs Metal Casting Technology Station MCTS is an initiative of the then Department of Science and Technology now Department of Science and Innovation - DSI under the Technology Innovation Agency TIA.

The MCTS operates under the Faculty of Engineering and the Built Environment in partnership with the Department of Metallurgy. For more information visit the MCTS. Metal casting technology station egoli address metal casting technology station egoli university of johannesburg metal casting technology station egoli.

The Metal Casting Technology Station Department at the University of Johannesburg South Africa on Academiaedu. Technology Stations The University currently hosts two Technology Stations namely. The Metal Casting Technology Station MCTS and the Process Energy and.

The Metal Casting Technology Station MCTS at the University of Johannesburg UJ is an initiative of the Department of Science and Technology DST and is. As a means to add value to the casting industry in South Africa the Metal Casting Technology Station MCTS located at the University of Johannesburg UJ. As a means to add value to the casting industry in South Africa the Metal Casting Technology Station MCTS located at the University of Johannesburg UJ.

Metal Casting Technology Station Room G101 John ORR Building Crn Siemert and Beit Street Doornfontein Johannesburg Tel. 27 11 559 6455 Contact Us. The Metal Casting Technology Station MCTS at the University of Johannesburg UJ was recently certified as ISO 90012008 compliant for the scope of Metal and Sand Testing.

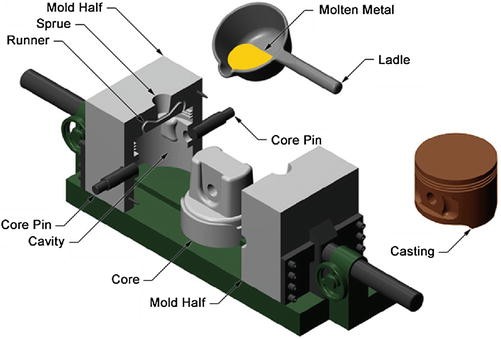

The accreditation was issued in December 2016 by the South African Bureau of Standards SABS. Metal Casting Technology is the act or process of producing casts by pouring molten metal into a cavity of shape as if component and allow freezing. Related Journals for Metal Casting Technology Powder Metallurgy Mining Journal of Materials Processing Technology International Journal of Metalcasting Transactions of Nonferrous Metals Society of China Physics of Metals and Metallography.

Semi-solid metal SSM casting is a modified die casting process that reduces or eliminates the residual porosity present in most die castings. Rather than using liquid metal as the feed material SSM casting uses a higher viscosity feed material that is partially solid and partially liquid. A modified die casting machine is used to inject the semi-solid slurry into reusable hardened steel dies.

The high viscosity of. Scrap metal dealer Alberton is a scrap metal company with a mission. It says so right there in the name.

Our mission is to save construction companies some money whilst doing demolitions for their next project. Scrap metal dealer Alberton are also fanatics for helping save the environment and we do so by recycling all of the metals that we clear from all demolition sites and take them to our companys scrap yard where we recycle and resell the metals. Successful case studies of metal casting applications using sand moulds and cores produced by additive manufacturing AM processes have been widely reported in the literature.

Furnace and casting copper axe beautiful ax chisel - YouTube. Technology or product developers RD specialists and government or NGO employees in scientific roles. The ZCast Direct Metal Casting process provides the ability to produce cast metal parts from a CAD file significantly faster and less expensively than traditional prototype casting methods.