The Fabric Finish refers to processestechniquesthings applied to the fabric after it is made to change its appearance hand or performance. Finishing is the final processing before the fabric is cut into apparel or made into any articles of textiles.

Fabrics and finishes play a very important role in any good project of interior design and decoration.

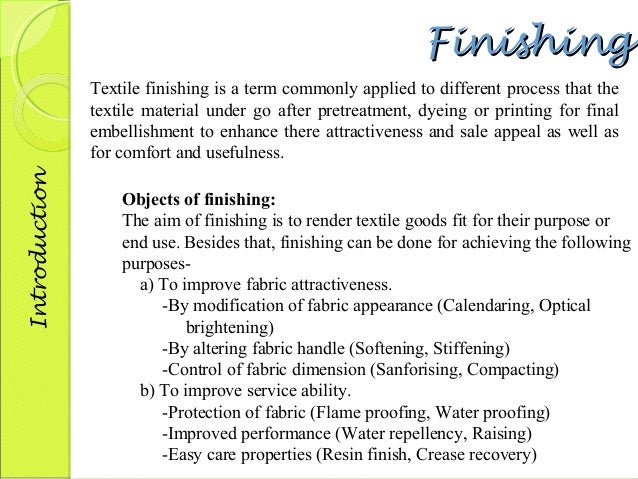

Importance of fabric finishes. Textile finishes are important because they help to improve the appearance. They also make the fabric more useful and suitable for an end specific use. Click to see full answer Consequently what is the purpose of fabric finishes.

Importance of Textile Finishes Textile finishes are important because of the following reasons. The finishes help to. Improve the appearance of fabric and enhance its looks.

Produce variety in fabrics through dyeing and printing. Improve the feel or touch of fabric. Make the fabric more useful.

Improve the draping ability of light weight fabrics. Make fabric suitable for an end specific use. Special finishes imparted to fabrics keeping the functional use of the fabric is known as special or functional finishes.

Although the cellulose fibers like cotton linen and rayon have good absorbency sometimes it is desired that they should be more absorbent. Appropriate application of ammonium compounds modifies the cellulose to become more absorbent providing greater comfort. Fabric finishing is the general term for this process.

Immediately after fabric is manufactured its raw and harsh and not yet ready to be made into fabric goods. At this stage the cloth is. Bulletproof finish on fabric saves the people from bullets and is generally used by defence and police personnel for their safety and crease-resistant.

Fabrics and finishes play a very important role in any good project of interior design and decoration. Therefore they are one of the most fundamental elements when it comes to achieving a specific presence and style getting them to define the character of the space that we want. Generally the chemical finishing of cotton fabric improves the appearance eg.

Mercerizing and or improves serviceability eg. Easy care or durable press flame retardant Water repellent etc Also chemical finishing may protect the cotton fabric against environmental condition such as protection from microbiological degradation. Lustre finishes produces a change in fabrics light reflectance by making them more shiny.

Permanent or temporary changes in surface pattern and luster of fabrics can be achieved through a variety of finishing techniques. Techniques such as calendering beetling and burning-out influence the resulting appearance of the fabric. Calendering is a mechanical process that finishes.

The Fabric Finish refers to processestechniquesthings applied to the fabric after it is made to change its appearance hand or performance. From the grey cloth from the manufacturing unit to the smooth fabric you cut up is a long list of many fabric finishes. Fabrics usually still need to undergo additional steps known as Finishing.

Finishing is the final processing before the fabric is cut into apparel or made into any articles of textiles. Finishing is what improves attractiveness and makes fabrics suitable for use. There are different types of finishing operation.

In dressmaking and designing fabric selection is vitally important and integral part. Different fabrics for required for different ages purposes and occasions. Wedding dress uniforms undergarments casual wears all require a different kind of fabrics and at times a combination of many.

By Textile School Last updated Mar 14 2019. Antistatic finishes are applied as an effective antistatic agent on the surface of the fiber and to the surface with which frictional contact is causing the potential charge accumulation. A fabric finish is a treatment given to change the appearance touch or performance of a fabric.

The goal is to enhance the fabric beyond its natural state to make it better suited for whatever its purpose is. Technically fabric finishes are divided into two categories. One design will not look same in different fabrics because of difference in their draping quality.

Drape of a fabric depends upon stiffness thickness weight etc. Stiffness one of the attributes. Functional finishes increase the utility or purpose of the fabric.

There are two basic genres of functional finishes and the most basic are the aesthetic finishes. These increase the appearance of. Functional finishes for textiles reviews the most important fabric finishes in the textile industry.

It discusses finishes designed to improve the comfort and other properties of fabrics as well as finishes which protect the fabric or the wearer. When applying antistatic finishes to fabrics uniform fabric penetration is important for optimal performance. The use of wetting agents in the finish formulation is recommended.

Pad spray and kiss-roll applications are favoured. Cationic antistats are suitable for exhaust processes.