When a flow of water is applied to one end of the tube it creates a vacuum sucking air in from the outside world. In 1797 Giovanni Battista Venturi performed experiments on flow in a cone-shaped tube and built the first flowmeter for closed pipes called the Venturi tube.

A venturi vacuum pump or aspirator works by using compressed air running through the pump.

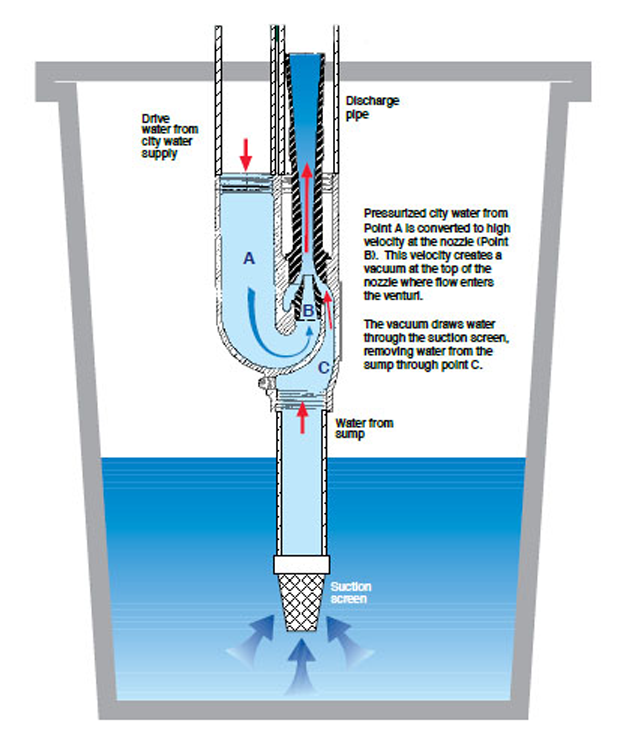

How venturi pump works. How does a venturi pump work. A venturi creates a constriction within a pipe classically an hourglass shape that varies the flow characteristics of a fluid either liquid or gas travelling through the tube. More commonly a venturi can use this negative pressure to draw a second fluid into the primary flow.

A Venturi pump uses the kinetic energy in a fast-moving fluid to move another liquid or semi-liquid substance. These pumps are abundant in sewage treatment plants because they reliably move large volumes of thick heterogeneous material without clogging or locking. Detailed animation showing how our Essig Venturi Water Pumps work.

This rugged simple and lightweight air operated pump that requires no priming and is capa. Pumps slurry mud and small stones without effort. Requires 80 cfm at 100 psi compressed air at the nozzle.

How does the V pump work. The V-Pump patented design utilises the venturi effect to maximise pumping capacity. The venturi effect occurs when liquid flows through a compressed section of pipe.

The result is increased fluid velocity reduced fluid pressure. A venturi creates a constriction within a pipe classically an hourglass shape that builds backpressure up-stream and effects a negative pressure down-stream of the constriction. As the volume of fluid is forced through the reduced diameter fluid dynamic laws determine that the increased flow velocity be accompanied by a pressure drop.

A venturi uses this negative pressure to draw air into the primary. As a result of Bernouli and Venturis work a Venturi vacuum is created by a pump with compressed air running through it however the pump has no moving parts. A venturi vacuum pump or aspirator works by using compressed air running through the pump.

It has no moving parts. It reduces pressure from a choke or constricted area so fluid can flow through. Venturi nozzles and tubes are used alongside the pump to.

A rugged simple and lightweight air operated pump that requires no priming and is capable of moving approximately 15000 litres of water per hour with a co. How does the Venturi System Work. A Venturi System reduces pressure when a fluid flows through a constricted section or choke of a pipe.

In 1797 Giovanni Battista Venturi performed experiments on flow in a cone-shaped tube and built the first flowmeter for closed pipes called the Venturi tube. A Venturi vacuum is created by a pump with compressed air running through it yet the. Some bilge pumps work using the Venturi effect.

They contain a hose which connects the bilge to an opening in the hull which is above sea level. When the vessel is sailing at a fast speed water enters the hose because of inertia tendency to stay stationary. Venturi pumps operate completely without moving parts except for the material moving through them.

They work on the principle of conservation of energy where high potential kinetic energy in one fluid entrains another fluid and then propels the mixture out of the pumping area. This quality makes them useful for pumping liquid with a high percentage of solids such as slurries or sewage without clogging. A variable venturi increases its size according to engines demands.

As the driver presses the throttle pedal the venturi size increases while it decreases when the throttle pedal is released. Thus airflow speed through the carburettor venturi and the resulting pressure difference remains constant. Basically the Venturi vacuum pump originally named a Bernoulli vacuum pump is a simple device that converts pressure potential energy to velocity kinetic energy when a fluid liquid or gas is forced through a restriction in an enclosed line which creates a partial vacuum in the process.

A vacuum ejector or simply ejector is a type of vacuum pump which produces vacuum by means of the Venturi effect. In an ejector a working fluid liquid or gaseous flows through a jet nozzle into a tube that first narrows and then expands in cross-sectional area. These pumps make use of their structure to transfer energy from one fluid to another via the Venturi effect.

A venturi is a simple device consisting of a tube which is narrow in the middle. In most aquarium venturis the plastic nozzle at the top contains the narrow point. When a flow of water is applied to one end of the tube it creates a vacuum sucking air in from the outside world.

Firstly it is worth noting that Ejectors are also known as Eductors Surface Jet Pumps Venturis or Velocity Spools. The operating principle is common to all regardless of name. Based upon Bernoullis Principle as the velocity of a fluid increases its pressure decreases and vice versa.