Its good corrosion resistance is on par with that of most standard stainless steel grades. Duplex 2304 is a 23 chromium 4 nickel molybdenum-free duplex stainless steel whose structure is a balance of ferritic and austenitic.

This makes them ideal for chemical processing and storage pressure vessels and tanks or high chloride environments for marine applications.

Duplex stainless steel yield strength. Annonce See our Forta range Stainless Steels for corrosive environments. Strength and Hardness of Duplex Stainless Steel Ultimate Tensile Strength. Ultimate tensile strength of duplex stainless steels SAF 2205 is 620 MPa.

Yield strength of duplex stainless steels SAF 2205 is 440 MPa. The yield point is the point on a. Yield strength of duplex stainless steels SAF 2205 is 440 MPa.

Yield strength of precipitation hardening steels 17-4PH stainless steel depends on heat treatment process but it is about 850 MPa. Duplex 2205 is a two-phase ferritic austenitic 22 chromium 3 molybdenum 5 to 6 nickel alloyed stainless steel. It is the most widely used duplex stainless steel grade and is characterized by high yield strength double that of the standard austenitic stainless steel grades.

It also demonstrates good fatigue strength as well as outstanding resistance to stress corrosion cracking crevice pitting erosion and. Rite duplex stainless steels combine mechanical strength with extremely high corrosion resistance. In fact duplex s yield strength is considerably superior to that of conven-tional stainless steels allowing for lighter constructions more compact system designs and less welding.

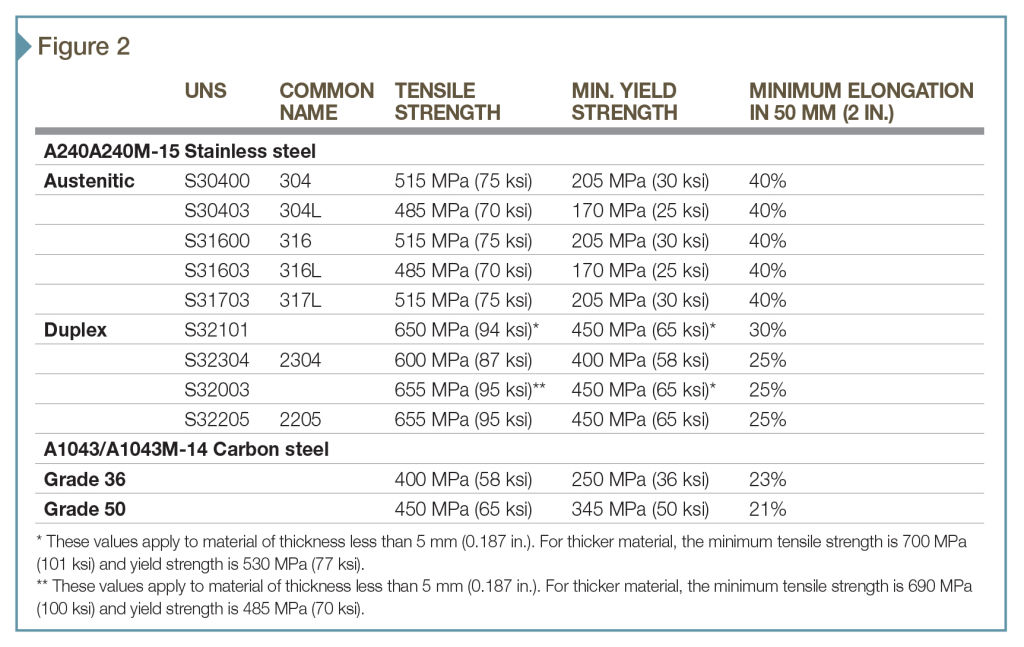

In tube applications for example duplex s higher. A 2205 duplex stainless steel has a minimum yield strength of 65ksi 450MPa compared with a minimum of just 25ksi 170MPa for Alloy 316L UNS S31603 14404. The yield strength for a super duplex grade either UNS S32750 F53 14410 or UNS S32760 F55 14501 is.

Duplex Stainless Steels have roughly twice the yield strength of their counterpart austenitic grades. This allows equipment designers to use thinner gauge material for vessel construction. Working with duplex 2205.

With nearly twice the yield strength of other comparable austenitic grades 2205 duplex steel products can withstand higher pressures and more corrosive environments with less material saving on weight and fabrication costs. This makes them ideal for chemical processing and storage pressure vessels and tanks or high chloride environments for marine applications. Due to the high yield strength of 2205 greater forces are required for the cold forming of this duplex steel and will require larger capacity equipment than would be required for austenitic steels.

Processes such as stretch forming deep-drawing and spinning are more difficult to perform. Duplex 2304 is a 23 chromium 4 nickel molybdenum-free duplex stainless steel whose structure is a balance of ferritic and austenitic. It has general corrosion resistance similar or better than Alloys 304L and 316L but with yield strength nearly double that of austenitic stainless steels.

Its duplex microstructure and low nickel and high chromium contents also allows Duplex 2304 to. LDX 2101 is a duplex austenitic-ferritic stainless steel with relatively low contents of alloying elements. The grade has high mechanical strength similar to that of other duplex grades.

Its good corrosion resistance is on par with that of most standard stainless steel grades. 2205 DuplexSuper Duplex Stainless Steel 14462UNS S31803UNS S32205 The yield strength is about twice that of austenitic stainless steels thus allowing a designer to save weight and making the alloy more cost competitive when compared to 316L or 317L. 2205 is the most widely used duplex ferriticaustenitic stainless steel grade.

It finds applications due to both excellent corrosion resistance and high strength. The standard duplex S31803 composition has over the years been refined by many steel suppliers and the resulting restricted composition range was endorsed as UNS S32205 in 1996. 2205 duplex stainless steel has high yield strength not only has strong chloride stress corrosion resistance but also has good comprehensive mechanical properties.

The market application prospect is broad. The welding process is complex and it is very important to ensure the phase proportion balance of the weld and HAZ. Duplex stainless steels are a specific group of engineering stainless steel materials consisting of the austenitic and ferritic phase in roughly equal proportions in the microstructure.

They are widely popular because of their good corrosion resistance along with high strength and ease of fabrication. Compared to traditional austenitic stainless steel and ferritic stainless steel grades. Annonce See our Forta range Stainless Steels for corrosive environments.