Usually pumps are needed to bring the fluids to the surface. The lower portion is typically held in place with cement.

The casing is fabricated in sections or joints that are usually about 40 feet long and screwed together to form longer lengths of casing called casing strings.

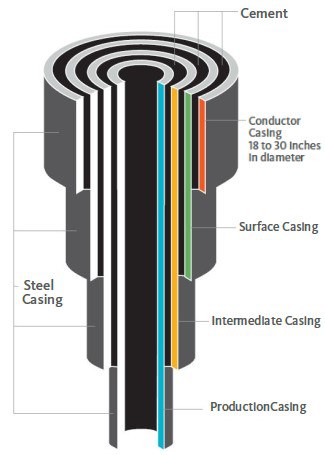

Casing oil and gas. Oil casing is a steel pipe used to support the walls of oil and gas wells to ensure the normal operation of the entire oil well after drilling and completion. Each well uses several layers of casing according to different drilling depths and geological conditions. A well with a high bottom hole temperature can use P-110 andor X-125 casing and P-105 tubing in the lower section of the hole up to a point where the static temperature is no longer high enough.

At this crossover temperature it is then necessary to run. Casing and tubing strings are the main parts of the well construction. All wells drilled for the purpose of oil or gas production or injecting materials into underground formations must be cased with material with sufficient strength and functionality.

Tubing transports the oil and gas from deep in the well to the surface the third phase of the wellbore. Oil and gas occasionally rise to the surface on their own. Usually pumps are needed to bring the fluids to the surface.

Tubing naturally has a smaller diameter than casing. Downhole casing leaks in oil- and gas-producing wells significantly affect. Their shallow water horizon the environment and fresh water resources.

Casing leaks may cause seepage of toxic gases to fresh water zones and the surface through the casing. The casing string provides a means of securing surface pressure control equipment and downhole production equipment such as the drilling blowout preventer BOP or production packer. Casing is available in a range of sizes and material grades.

BOP casing grade casing joint. The casing is fabricated in sections or joints that are usually about 40 feet long and screwed together to form longer lengths of casing called casing strings. Once casing is installed and cemented the rig will then continue drilling with a smaller sized bit until they reach TD or need to install the next casing string.

The last string of casing that is installed is called the production casing. This casing string is installed through the. An Update on the Use of Fiberglass Casing and Tubing in Oil and Gas Wells Mahmood Amani Ahmed Abdul Rauf Texas AM University at Qatar 1.

INTRODUCTION Fiberglass or Fiber Reinforced Plastic FRP tubulars have been in use in the oil and gas industry since the 1980s. A wide range of applications have been identified including but certainly not. RBP The oil and gas industry uses many acronyms and abbreviations.

This list is meant for indicative purposes only and should not be relied upon for anything but general information. 2015 Casing Reference Tables World OilJANUARY 2015 C109 Dimension nomenclature D Casing nominal OD of tube in. W Casing weight lbft d ID drift in.

This video describes the different types of casing used for well construction. By the time a well is drilled to its final depth it usually has several stri. Casing design principles - Oil and Gas well design - YouTube.

This is basic casing design. Pls SUBSRIBE for more video. As far as burst is concerned the most common procedure is to assume that the casing must withstand the maximum shutin formation pressure in the form of a gas column for a gas well or oil for an oil well from the perforations all the way to the surface.

Casing is a large diameter pipe that is assembled and inserted into a recently drilled section of a borehole. Similar to the bones of a spine protecting the spinal cord casing is set inside the drilled borehole to protect and support the wellstream. The lower portion is typically held in place with cement.

Deeper strings usually are not cemented all the way to the surface so the weight of the pipe must be partially supported by a casing. Well Completions A wellhead component used in flanged wellhead assemblies to secure the upper end of a casing string. Casing spools or bowls are available in a wide range of sizes and pressure ratings and are selected to suit the specific conditions.

We can use liner hanger system assembly to support hinge the casing liner on the previous casing string in oil and gas drilling wells. Check Types Of Casing Article. In general there are many reasons to choose using a casing liner hanger.

As it is much cheaper than running casing especially in deep oil and gas wells. Faulty oil and gas wellbores are a primary pathway of concern for gas migration from the deep subsurface into shallow freshwater aquifers. Leaked gases migrating vertically along wellbores either collect and build a pressure at the wellhead known as sustained casing pressure SCP or escape into the atmosphere as surface casing vent flow SCVF.

Casing design is an important task in oil and gas well design. Casing design involves evaluation of the factors that con tribute to the failure of the casing and proper se lection of the most.