Oil extraction from algae is a hotly debated topic currently because this process is one of the more costly processes which can determine sustainability of algae-based biodiesel. Expenditures for this venture.

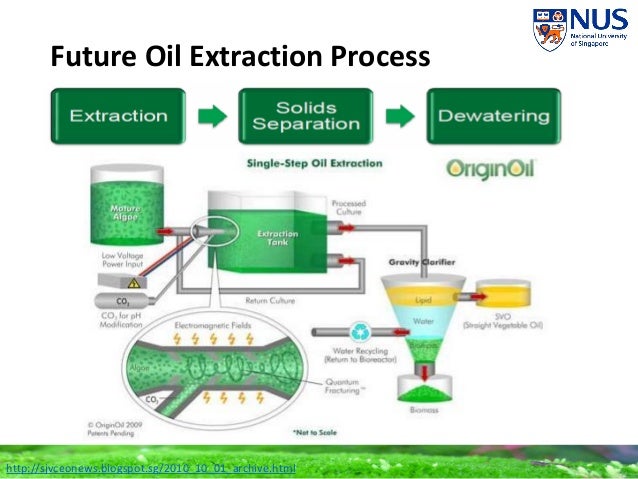

Finally we needed to design an efficient system for processing the algae to release its oils.

Algae oil extraction process. Most manufacturers of algae oil use a combination of mechanical pressing and chemical solvents in extracting oil. Commercial Scale Algae Oil Extraction. Enzymatic extraction - Enzymatic extraction uses enzymes to degrade the cell walls with water acting as the solvent this makes fractionation of the oil much easier.

The costs of this extraction process are estimated to be much greater than hexane extraction. Oil extraction from algae is a hotly debated topic currently because this process is one of the more costly processes which can determine sustainability of algae-based biodiesel. Various methods to extract the oil from microalgae are available such as expellerpress solvent extraction and supercritical fluid extraction 2.

Expeller pressing is the. After being harvested algae oil must be extracted before being transesterified to biodiesel. This process which generates a carbon-neutral renewable liquid fuel has been shown to be competitive with other liquid fuel sources Silva et al 2014.

Discovered that a dry extraction process using hexane as a chemical medium would worth pursuing we then needed to begin work on a system for drying the algae. Finally we needed to design an efficient system for processing the algae to release its oils. Supercritical CO 2 Process uses liquid CO 2 at high temperature and high pressure to extract algae oil CO 2 penetrates algae cells and causes them to rupture Widely used in various industries including coffee Advantages Low environmental impact High quality oil and biomass product Limitations.

The application of ultrasonication to the production of biodiesel from algae is not limited to the extraction of oil from algae. Biodiesel is made from algae oil by a chemical conversion process called transesterification. Despite the use of heat mechanical agitation and catalytic chemicals this conversion takes approx.

4 to 6 hours. In less than. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

Ground algae to extract oil in separating funnel of 250 ml. Then the mixture was kept for 24 h for settling and for separation of the two layers in the funnel. The organic phase containing the algae oil was emptied in the pre-weighted 50 ml beaker.

The Algal oil was separated from Algae biomass by. This chapter aims to summarize the recent developments in microalgal oil extraction processes including drying methods cell disruption methods conventional or supercritical solvent extraction. Chemical Engineering 1705 Final Project.

Extraction of oil from algae using hexane and Soxhlet extraction. Expenditures for this venture. Regarding the extraction of the oils supercritical carbon dioxide is a green non-toxic solvent that can be used to extract and convert algae-oils to biodiesel in a single step eliminating the need for pre- or post-processing of the oil or.

Oil extraction is defined as the process of separating triglyceride TAG lipids from the harvested and concentrated algal biomass and it could be done through a variety of mechanical or chemical manipulation techniques. Oil extraction using hexane solvent has been considered in this study using a stripper column model 27.